By Dean Stanley

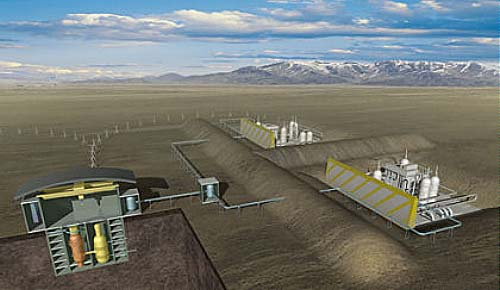

A nuclear plant employing four Gen IV modular helium reactors could produce enough hydrogen to fuel more than one million fuel cell vehicles every day, according to the engineers at General Atomics.

As the automotive industry speeds the development of commercially viable fuel cell vehicles, the biggest roadblock facing all parties is a wide-ranging infrastructure -- without this, the future hydrogen economy will likely stall.

While interim solutions such as natural gas reforming can support limited numbers of fuel cell vehicles early on, a full-scale hydrogen infrastructure is necessary to assure public acceptance in an expanding market. But will it happen? According to the nuclear industry, it can.

Of the six Gen IV reactor designs under consideration by the Gen IV International Forum (GIF), the Very High Temperature Reactor (VHTR) is the one that has received the most attention. Of VHTRs, General Atomics’ Gas Turbine Modular Helium Reactor (GT-MHR) has become a major candidate in the quest for nuclear-based hydrogen production, either through high-temperature electrolysis or thermochemical means.

Able to run on a variety of fuels, from processed uranium and spent light water reactor to weapons-grade plutonium, the GT-MHR can be run efficiently for either electricity generation or hydrogen production. A single, four-module GT-MHR power plant, with a total thermal output of 2.4 gigawatts could produce fuel for more than one million fuel cell cars every day, according to engineers at General Atomics.

However, the job of supplanting petroleum as an automotive energy source is tremendous, even for nuclear power. According to INL engineers, it would require somewhere between 500 and 1,000 nuclear-powered hydrogen plants to completely replace the United State’s transportation fuel needs. Industry insiders don’t claim that nuclear-generated hydrogen will alone replace petroleum. But they do suggest that it will contribute greatly to alleviating U.S. dependence on foreign oil.

While electricity by itself can be used to create hydrogen from water using low-temperature electrolysis, taking advantage of a Gen IV reactor’s much higher operating temperature means thermochemical and high-temperature water splitting are not only possible, but much more efficient.

Low temperature electrolysis using electricity generated by current light water reactors (LWRs) has an efficiency of about 24-percent, while a high-temperature reactor, like the GT-MHR, would yield 36-percent efficiency. These figures are based on electrolyzers that operate at atmospheric pressure. “There are some high-pressure units that are under development that would be somewhat more efficient,” says Dr. Steve Herring of the Idaho National Laboratory.

Both high-temperature electrolysis and thermochemical water splitting -- using advanced Gen IV reactor technology -- raise efficiency to nearly 50-percent, though the biggest advantage of thermochemical is the lack of electrical cost, according to Herring, who has been working with engineers at Ceramatc to develop the high-temperature electrolysis. Both thermochemical water splitting and high-temperature electrolysis are still in the research phase, though electrolysis is closer at hand. In either case, high-temperature hydrogen production technology will likely be in place sooner than the reactors needed to drive it.

Entire contents © 2006 Corland Publishing. Use of editorial content without permission is strictly prohibited.

All Rights Reserved. Privacy Policy Legal Contact Us. Site developed by ICON.