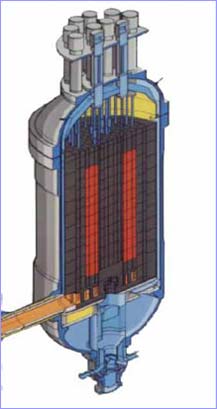

Showing the most potential, according to experts, is General Atomics’ gas turbine-modular helium reactor (GT-MHR) concept. Based on the Gen IV VHTR design, the GT-MHR would be at the heart of future hydrogen-electric generating plants.

Using reprocessed nuclear fuel, Gen IV reactors, such as this General Atomics' GT-MHR concept, may offer a significant long-term source of carbon-free hydrogen within 20 to 30 years.

General Atomic’s full-scale plant design allows up to four 600-megawatt (thermal) GT-MHR reactors each capable of producing 300 megawatts of electricity or 200 tons of hydrogen day with 50-percent efficiency -- a four-module hydrogen plant could theoretically supply enough hydrogen to fuel 1.2 million fuel cell vehicles, but those modules could also be mixed and matched, according to Dr. Kenneth Schultz of General Atomics.

“If you build multiple modules, there’s no reason that some of the modules couldn’t be used for electricity and some for hydrogen,” says Schultz, adding that each module must be dedicated to either electricity generation or hydrogen production. The modular character of this proposed plant design would also allow future expansion based on changing requirements.

“I envision that our first customers will likely be ammonia production plants and oil refineries. However, we are not moving ahead as quickly as we’d like to, and GM is catching up, so maybe it will be fuel cell cars first,” Schultz suggests.

Electrical Power

For the grid, the GT-MHR would use the same technology found in modern jet engines, employing the high-temperature helium coolant as a driving gas, versus water-steam used in the LWR plants currently in operation around the U.S. and throughout the world. In a powerplant application the actual design requirements are less demanding, according to General Atomics, with temperatures, stresses and blade tip speeds all far below those proven in millions of hours of aircraft engine operation.

While many of the components that make up this gas turbine design, additional work is still needed to integrate them into the most economical and reliable package -- such as the turbine’s advanced zero-friction active magnetic bearings, which control shaft stability while eliminating the need for lubricant within the primary system.

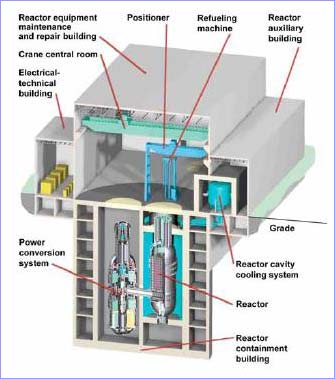

The entire GT-MHR power plant would be contained in two interconnected pressure vessels enclosed in a below-ground concrete containment structure -- one vessel for the reactor and the other containing the power conversion equipment.

Unlike older LWR plants, the GT-MHR places all the critical reactor components below grade for better protection from terrorist threats.

The second vessel includes a turbine and two compressor sections mounted on a single shaft connected to a generator. The vessel would also contain three compact heat exchangers -- the most important of which is a 95-percent effective recuperator used to recover turbine exhaust heat, boosting plant efficiency from 34 percent to 48 percent, according to General Atomics.

Entire contents © 2006 Corland Publishing. Use of editorial content without permission is strictly prohibited.

All Rights Reserved. Privacy Policy Legal Contact Us. Site developed by ICON.